Mick Payne brings some sound advice about keeping your bike in one piece as he revisits stainless steel nut and bolt manufacturer D Middleton & Son.

Until I retired, I worked as an engineering designer, apprenticed at bearing manufacturer SKF and finally working on the propulsion systems of satellites.

The common denominator of much of this engineering is the good old nut and bolt, but where spacecraft are concerned, bonding is a popular method of securing items.

Enjoy more Old Bike Mart reading in the monthly newspaper.

Click here to subscribe & save.

Yes, they are pretty much glued together, but not with your average shop-bought glues!

SKF, being Swedish, used metric, but imperial ruled the roost in my next job, at British Leyland, and in 40 years in engineering, metric and ‘British’ have featured about equally. Bikes have been the same: from a Lambretta at 16 to British iron the nuts and bolts have changed.

Good grief, you must be thinking, not only did he help design press-tools for the Mini Metro, but he started riding on a scooter! But don’t worry, both are behind me and the counselling has worked wonders…

These days, very little made is bolted together with anything other than fastenings measured in millimetres, but OBM readers will own bikes taking in the whole gamut of thread forms, and boy there are many.

Threaded items go back centuries, but at first were not really compatible, each nut and bolt being made as a pair, and it was only when the need for interchangeability arose that standardisation became necessary. In the UK in 1841, Joseph Whitworth created a design that would be dubbed British Standard Whitworth – proper engineering had arrived!

Other thread forms were devised to cover all eventualities, but during the Second World War standardisation was needed across the Allied nations, which led to the Unified Thread Standard. This gave us Unified Coarse (UNC) and Unified Fine (UNF), both much used on later British bikes.

Later came the SI standardisation of metric screw threads from the French ‘Systeme International’, pretty much today’s standard, and not an altogether bad thing. This has also given the world the slightly derisory term ‘Metric Cruiser’ from those who prefer the American item. Yes the great HD has hung on to unified threads.

My first British bike was a Triumph T140E, and it had Unified Threads (mostly) and the nice thing was that they were mostly cap heads, better known as Allen screws.

This made a change from the soft cross-heads on the Japanese bikes I’d previously owned (we’ll discount the Lammy), and the only quality fastenings I’d experienced until then had been on a 1975 MZ 250 and a couple of Guzzis.

Around 1982 I started to replace the blackening cadmium-plated screws with stainless steel, and it was to Yorkshire-based Dave Middleton that I turned. I must have helped the fledgling firm to profit as I systematically changed all the fastenings to stainless.

At the time, stainless was under suspicion with good old Motorcycle Sport, whose army of letter writers proclaimed doom and gloom for anyone misguided enough to use the high-chromium material.

“High tensile is king” was the mantra. I ran that Bonnie for over 30 years, and never had any sort of failure that could be attributed to my choice of material.

Not only is Dave Middleton still in business and specialising in stainless steel, but his son Richard is also involved now. “I started working with my dad around 2003 and became a partner shortly after, when we became D Middleton and Son,” he said.

Bearing in mind that Dave was around 37 when he started out and is now reaching retirement age, it really is great to see Richard taking the business further into the current century.

When I first started dealing with Dave, he published lists for British bikes selling sets of fasteners for various locations.

For instance, for the rocker covers on a T140 it would be a set of 12 off ¼ UNC cap-head screws – just take out the original and replace with the new ones individually and the joint need not be disturbed. Don’t forget the thread lubricant, though.

Copaslip or something similar is necessary to avoid galvanic corrosion between the screw and alloy casting. Could stuck screws be the reason for all the bad press?

Of course in 2016, a website is an essential item for many a successful business. Richard explained that they’d had a website, designed to the company’s own requirements by a local web company, for around six years now.

This must make their life so much easier, as well as enabling customers to order more efficiently. Back in the day, everything I bought was by filling in a paper form and sending off a cheque. Times they are a-changin!

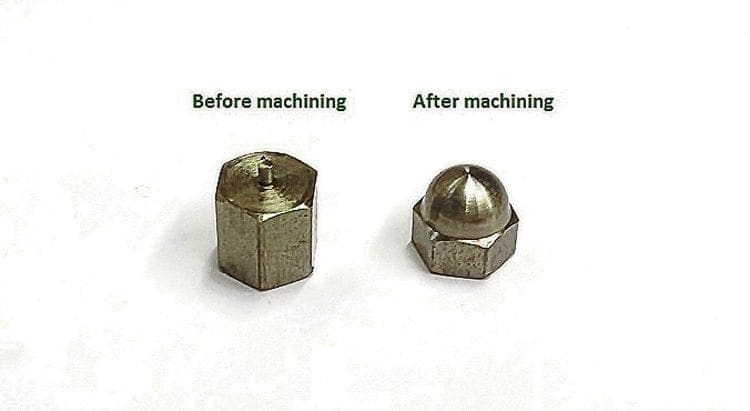

Back in the 1980s a major selling point was the fact that all their hex-head bolts above 3/16 or M5 had the ugly codes machined off to give a nice turned finish. “We still machine off any unsightly lettering above those sizes,” explained Richard.

There are still only Richard and Dave working there, and this keeps things simple and consistent. Richard also pointed out that they make the vast majority of fastenings themselves.

“Bolts, machine screws and standard nuts in British sizes above 3/16 BSCY, BSF and BSW as well as Metric Fine bolts and nuts are all machined on our CNC lathe,” said Richard, and the vast majority are for customers involved in classic and vintage motorcycle restoration.

D Middleton & Son also have customers with cars and boats, and will make batches of special items to a minimum order of 100.

It’s good to be able to recommend a business on personal experience although I haven’t used them for a while, because once you’ve replaced your bike’s various nuts and bolts with stainless there’s no need ever to do it again unless they vibrate off – and as long as you’re not an originality freak, their self-locking nuts will even prevent that from happening!

It really is great to see the business looking good for the future with Richard becoming involved, and I for one wish them well.

■ Email:

[email protected]

■ Website: stainlessmiddleton.co.uk

■ Address: Unit 5, Lady Ann Mills, Lady Ann Road, Batley, WF17 0PS

■ Phone: 01924 470807

Read more News and Features at www.oldbikemart.co.uk and in the latest issue of Old Bike Mart – on sale now!

Advert

Enjoy more Old Bike Mart reading in the monthly paper. Click here to subscribe.

Enjoy more Old Bike Mart reading in the monthly paper. Click here to subscribe.